When planning a project, you need materials that are clear, light, and strong. Many professionals and DIYers often choose between acrylic sheets and polycarbonate sheets.

At first glance, both materials may seem interchangeable. But the reality is, each comes with its own set of strengths, weaknesses, and ideal use cases.

So, how do you decide which one is right for your application?

This guide is from Jigar Plast. They are a reliable supplier of high-quality acrylic sheets. It will help you learn the key differences between acrylic and polycarbonate. This way, you can make a confident and informed choice.

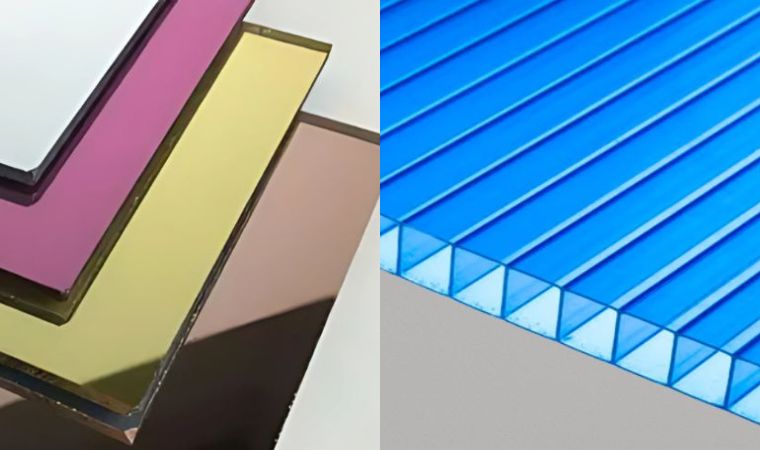

Acrylic, often marketed as Plexiglass, is a transparent thermoplastic known for its glass-like clarity and excellent weather resistance. Many people widely use it in signage, display panels, interior design elements, and skylights.

Polycarbonate sheet is a strong, impact-resistant plastic used in more demanding environments. People frequently use it in security applications, machine enclosures, protective barriers, and roofing systems that require extra strength.

Feature | Acrylic Sheets | Polycarbonate Sheets |

Clarity :- | Higher (glass-like, glossy) | Slightly lower (may yellow over time) |

Impact Resistance :- | Moderate (10x stronger than glass) | Very High (used in riot shields) |

UV Resistance :- | Naturally UV-resistant | Requires UV coating |

Fabrication Ease :- | Easy to cut, laser, and polish | Requires more care to cut cleanly |

Heat Resistance :- | Up to 80°C | Up to 115°C |

Fire Retardancy :- | Flammable | Available in fire-safe grades |

Price :- | More affordable | More expensive |

Here’s how to decide based on your specific needs:

Application | Recommended Material |

Advertising and retail signage | Acrylic |

Decorative interior panels | Acrylic |

Safety barriers and machine guards | Polycarbonate |

Pergola or skylight roofing | Acrylic (UV-resistant) |

Greenhouses and terrace covers | Acrylic or UV-coated PC |

High-impact industrial roofing | Polycarbonate |

DIY craft and furniture projects | Acrylic |

Protective glazing and riot shields | Polycarbonate |

For good value without losing clarity or quality, acrylic sheets are usually 30–40% cheaper than polycarbonate.

For many non-industrial projects, especially those where design and visibility are important, acrylic is a great choice. It provides a good mix of durability and looks at a lower cost.

Larger structures require thicker sheets to handle weather, impact, and structural load.

Jigar Plast is a well-known acrylic dealer. They supply high-quality acrylic sheets in many colours, thicknesses, and finishes. No matter your role, we can help you.

Whether you are an interior designer, a signage maker, or a contractor, our expert team is here for you. We will assist you in choosing the best material for your needs. We offer competitive prices and consistent quality.

We also supply polycarbonate sheets for customers who require high-impact performance and industrial-grade durability.

The debate between acrylic vs. polycarbonate boils down to what your project demands:

If you’re still unsure, connect with Jigar Plast. We’ll help you assess your needs and deliver the right solution — fast, affordable, and reliable.

At Jigar Plast, we specialise in supplying high-quality acrylic and polycarbonate sheets that drive creativity across various industries. From signage and LED lighting to architectural, display, and interior applications, our products are trusted for their durability, clarity, and versatility.